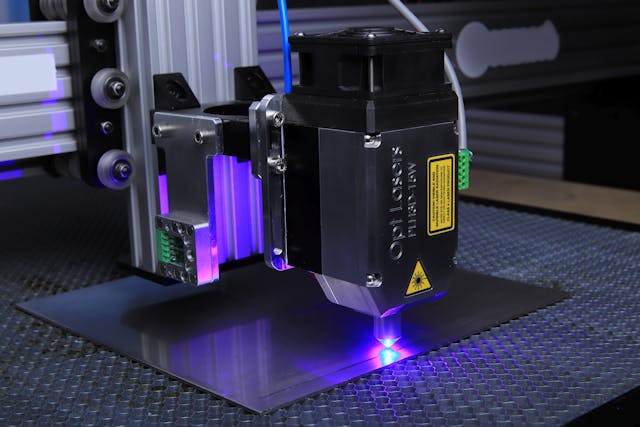

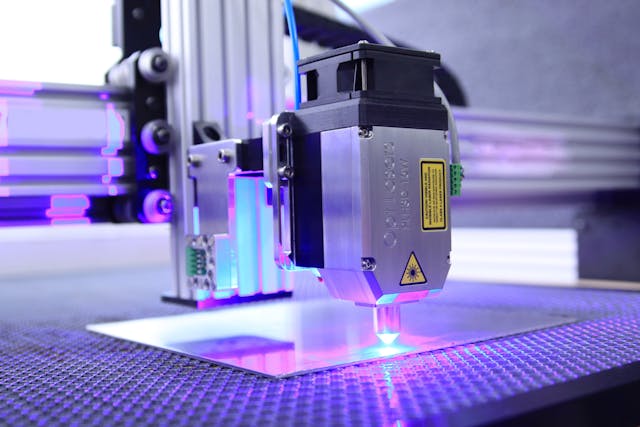

Since its origin, laser cutting technology has advanced significantly, always changing to meet the demands of contemporary production. This cutting-edge technique uses a focused laser beam to cut and shape materials with accuracy and efficiency. From consumer electronics to aerospace, new applications and improved capabilities are being fueled by advancements in laser cutting technology.

The Development of Laser Cutting Technology

The invention of the first laser by Theodore H. Maiman in the 1960s marked the beginning of the development of laser cutting technology. Lasers were first employed in scientific studies but soon found utility in industrial contexts. Significant progress has been made over the years, resulting in more potent, effective, and adaptable laser cutting.

Different Laser Types for Cutting Technologies

- One of the most popular types of lasers used in industrial laser cutting are CO2 lasers. Among the many materials that CO2 lasers can effectively cut, engrave, and bore are metals, polymers, glass, and wood. Their great power and efficiency are well known.

- Fiber Lasers: Because of their remarkable efficiency and beam quality, fiber lasers have become more and more common. They work especially well for cutting metal, such as copper, aluminum, and steel. Compared to CO2 lasers, fiber lasers are more energy-efficient and have a longer operational life.

- Crystal lasers: Used for high-precision cutting applications, crystal lasers include Nd and Nd lasers. They are frequently used in the electronics and medical device industries and are perfect for cutting ceramics and metals.

Recent Innovations in Laser Cutting

- New Developments in High-Power Laser Cutting: The speed and thickness of materials that can be sliced have been greatly boosted with the invention of high-power lasers. Productivity may now be increased by using lasers with power outputs of up to 10 kW or more to easily cut through thick metal sheets.

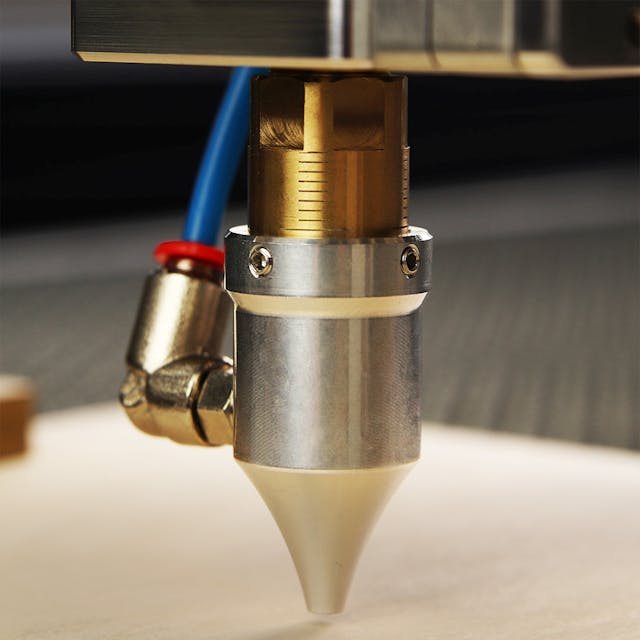

- Advanced Beam Shaping: Technological advancements in beam shaping give laser beam profiles more exact control. This leads to better edge quality, cleaner cuts, and decreased heat distortion—all of which are crucial in applications requiring extreme precision.

- Automation and CNC Integration: Manufacturing has been transformed by the combination of laser cutting technology and computer numerical control (CNC) systems. Automated laser cutting devices may run constantly with little need for human intervention, which boosts productivity and lowers labor expenses.

- Hybrid Systems: Hybrid laser cutting systems combine traditional machining methods with laser cutting, offering the advantages of both technologies. These systems can perform multiple operations in a single setup, further streamlining the manufacturing process.

- Eco-Friendly Solutions: As sustainability becomes a priority, innovations in laser cutting are focusing on reducing energy consumption and material waste. Energy-efficient lasers and optimized cutting algorithms contribute to greener manufacturing practices.

Applications of Advanced Laser Cutting

- Aerospace: The aerospace industry relies on laser cutting for producing lightweight and durable components. The precision and efficiency of laser cutting ensure that parts meet the stringent standards required for aerospace applications.

- Automotive: Laser cutting is used to manufacture various automotive components, from engine parts to body panels. The technology’s ability to cut complex shapes quickly and accurately makes it ideal for the automotive sector.

- Consumer Electronics: The miniaturization of electronic devices necessitates precise cutting of small and intricate components. Laser cutting Australia provides the accuracy needed to produce high-quality parts for smartphones, tablets, and other gadgets.

- Medical Devices: The medical field benefits from laser cutting’s precision for creating surgical instruments, implants, and diagnostic devices. The technology ensures that these critical components are made to exact specifications.

- Architectural and Artistic Applications: Laser cutting is increasingly used in architecture and art for creating detailed models, custom structures, and decorative elements. Its ability to cut complex designs with high precision opens new creative possibilities.

Laser cutting technology continues to evolve, driving innovation and efficiency in manufacturing. With advancements in high-power lasers, beam shaping, automation, hybrid systems, and eco-friendly solutions, laser cutting is poised to shape the future of various industries.